Tang, H., Liao, Z., Chen, Q., Xu, H., Huang, J., Han, J., Hu, D., Luo, Y., Lu, S., Baran, D., Li, G., Brabec, C.J., Laquai, F., He, Y.

Joule 8, 2208–2219, 2024

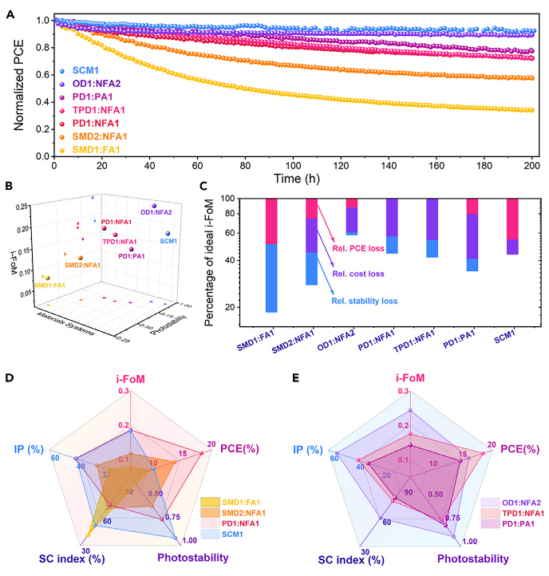

The choice of donor (D) and acceptor (A) materials in organic solar cells (OSCs) determines the so-called golden triangle of organic photovoltaics (OPV), namely, cost, power conversion efficiency (PCE), and device stability. However, despite the recent advancements in material and device development, determining the optimal material combination for industrialization remains a challenge. Herein, we unveil the optimal material combination that exhibits maximum industrial viability. Specifically, the industrial figure of merit (i-FoM) of seven OPV categories is calculated and further analyzed, including blends of small-molecule

donor (SMD):fullerene acceptor, SMD:non-fullerene acceptor (NFA), oligomer donor:NFA, terpolymer:NFA, polymer donor:NFA, polymer donor:polymer acceptor, and single-component materials. Because OPV is approaching wide-scale industrialization, insights into the successes and challenges of these material combinations, particularly their PCE, photostability, and synthetic complexity (SC) index, offer guidance toward accelerating the industrialization of OPV

Tang, H., Liao, Z., Chen, Q., Xu, H., Huang, J., Han, J., Hu, D., Luo, Y., Lu, S., Baran, D., Li, G., Brabec, C.J., Laquai, F., He, Y.

Joule 8, 2208–2219, 2024

The choice of donor (D) and acceptor (A) materials in organic solar cells (OSCs) determines the so-called golden triangle of organic photovoltaics (OPV), namely, cost, power conversion efficiency (PCE), and device stability. However, despite the recent advancements in material and device development, determining the optimal material combination for industrialization remains a challenge. Herein, we unveil the optimal material combination that exhibits maximum industrial viability. Specifically, the industrial figure of merit (i-FoM) of seven OPV categories is calculated and further analyzed, including blends of small-molecule

donor (SMD):fullerene acceptor, SMD:non-fullerene acceptor (NFA), oligomer donor:NFA, terpolymer:NFA, polymer donor:NFA, polymer donor:polymer acceptor, and single-component materials. Because OPV is approaching wide-scale industrialization, insights into the successes and challenges of these material combinations, particularly their PCE, photostability, and synthetic complexity (SC) index, offer guidance toward accelerating the industrialization of OPV