Sun, R., Yuan, X., Yang, X., Wu, Y., Shao, Y., Wu, X., Brabec, C.J., Min, J.

Joule 8, 1–16, 2024

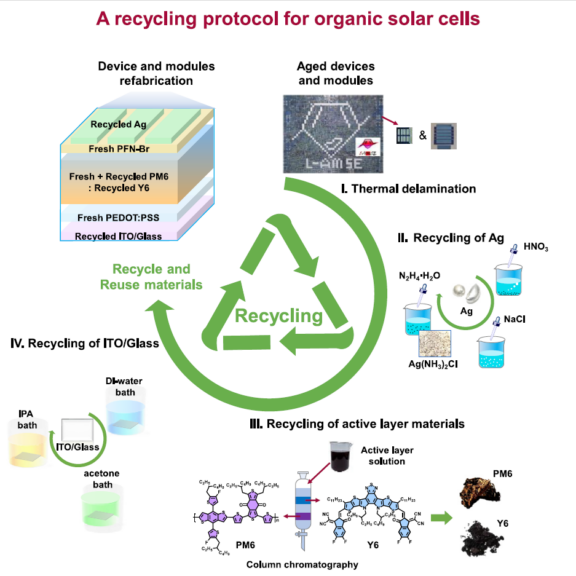

The vast majority of research on organic photovoltaics (OPVs) has focused on improving device efficiency and stability and reducing material costs. However, if one could refurbish OPVs, their stability might not be so demanding, and the reuse of valuable OPV components can

reduce the price per watt of solar modules. Herein, we present a dismantling procedure for reusing the active-layer materials without causing performance losses and for recovering the silver electrode and indium tin oxide (ITO)-electrode substrate via chemical and physical processes. Combined with the developed physical mixing methodology, the OPVs fabricated from recycled components also show comparable performance to that of fresh devices. The potential economic anal-

ysis points out that this recycling protocol can save 14.24 $ m2 in industrial scenarios, strongly demonstrating the possibility of recycling OPVs. This work represents a significant step toward cost-effective, high-yield recycling of waste OPVs while also demonstrating the prospects of no material supply constraints for OPV manufacturing shortly.

Sun, R., Yuan, X., Yang, X., Wu, Y., Shao, Y., Wu, X., Brabec, C.J., Min, J.

Joule 8, 1–16, 2024

The vast majority of research on organic photovoltaics (OPVs) has focused on improving device efficiency and stability and reducing material costs. However, if one could refurbish OPVs, their stability might not be so demanding, and the reuse of valuable OPV components can

reduce the price per watt of solar modules. Herein, we present a dismantling procedure for reusing the active-layer materials without causing performance losses and for recovering the silver electrode and indium tin oxide (ITO)-electrode substrate via chemical and physical processes. Combined with the developed physical mixing methodology, the OPVs fabricated from recycled components also show comparable performance to that of fresh devices. The potential economic anal-

ysis points out that this recycling protocol can save 14.24 $ m2 in industrial scenarios, strongly demonstrating the possibility of recycling OPVs. This work represents a significant step toward cost-effective, high-yield recycling of waste OPVs while also demonstrating the prospects of no material supply constraints for OPV manufacturing shortly.