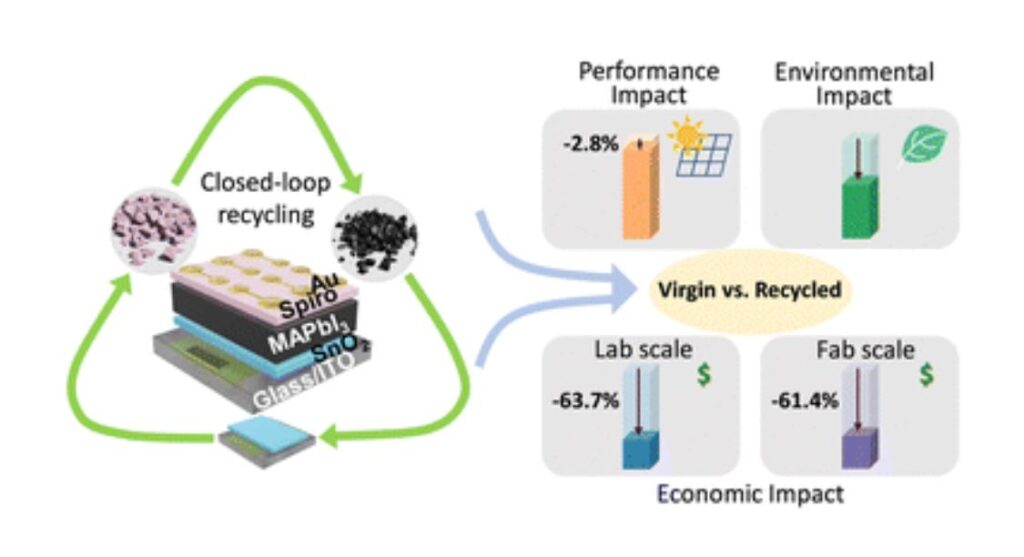

In a recent study published in Energy & Environmental Science, FAU Solar Marius Peter’s group has developed a new recycling method for MAPbI3 perovskite solar cells that uses a layer-by-layer solvent extraction technique. This process has shown the potential to recycle up to 99.97% of the material, aiming to reduce waste and conserve resources. The technique involves separating each layer of the solar cell, followed by processes to purify or modify the materials so they can be reused. Initial tests indicate that solar cells made with recycled materials perform comparably to those made with new materials, suggesting that this method could help maintain production quality while utilizing recycled components. Economic analysis from the study suggests that this recycling method could lead to cost reductions in material expenses, which could be beneficial for both laboratory and industrial-scale production. The method also appears to have a favorable impact on the environment by potentially lowering greenhouse gas emissions. This new approach could contribute positively to the photovoltaic industry by offering a more sustainable way to manage solar cell materials, aligning with ongoing efforts to enhance the environmental sustainability of solar technologies.

In a recent study published in Energy & Environmental Science, FAU Solar Marius Peter’s group has developed a new recycling method for MAPbI3 perovskite solar cells that uses a layer-by-layer solvent extraction technique. This process has shown the potential to recycle up to 99.97% of the material, aiming to reduce waste and conserve resources. The technique involves separating each layer of the solar cell, followed by processes to purify or modify the materials so they can be reused. Initial tests indicate that solar cells made with recycled materials perform comparably to those made with new materials, suggesting that this method could help maintain production quality while utilizing recycled components. Economic analysis from the study suggests that this recycling method could lead to cost reductions in material expenses, which could be beneficial for both laboratory and industrial-scale production. The method also appears to have a favorable impact on the environment by potentially lowering greenhouse gas emissions. This new approach could contribute positively to the photovoltaic industry by offering a more sustainable way to manage solar cell materials, aligning with ongoing efforts to enhance the environmental sustainability of solar technologies.