On sunny days, up to 60% of the electricity in Germany is produced by photovoltaics (PV). This is good news to fight climate change, but the land use by large PV fields is a problem that must be addressed. PV integration is therefore gaining importance, for example in buildings and green houses, for which novel organic PV materials are excellently suited. However, the performance of these materials critically depends on microstructure. Thus, slow and often destructive characterization methods are needed, severely retarding materials discovery towards a real breakthrough. To accelerate materials discovery, one would need to take the right decisions based on a faster assessment of microstructure. In the engineering world, digital twins are used for exactly that purpose, namely supporting real-time decisions even if information is scarce and indirect.

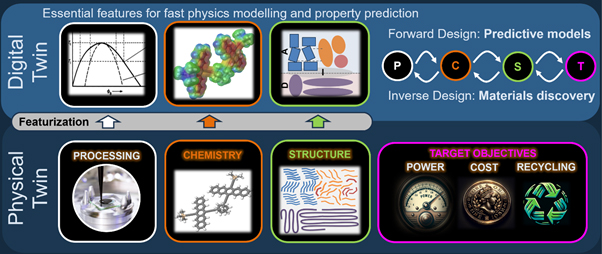

FAU Solar is teaming up with factory automation and artificial intelligence to learn how the concept of a Digital Twin could accelerate materials discovery. As a result, we propose a layout of a Digital Twin for PV materials, which has been recently published in “Joule”. The idea is to turn the famous “curse of dimensionality” from a problem into a feature: it is known that one can predict performance from microstructure but one can’t predict microstructure from performance, because many different microstructures would produce exactly the same performance. The point is however: if they do, then why distinguish them? All we need to know is the set of features that characterizes all these microstructures. Knowing the right features is the key to acceleration: on one hand, these features can be found by much simpler experiments, such as absorption spectroscopy. On the other hand, knowing the right features can also speed up physics models tremendously, which is why experts in solid state calculations and advanced mathematics are part of the consortium. In feature space, fast surrogate functions can be found which can be used to predict performance from structure, but most importantly, they can be used in the opposite direction, discovering new molecules with desired properties. Many of the enabling technologies still must be further developed to bring the digital twin to full performance, but even before these technologies are available, the digital twin can accelerate material science.

On sunny days, up to 60% of the electricity in Germany is produced by photovoltaics (PV). This is good news to fight climate change, but the land use by large PV fields is a problem that must be addressed. PV integration is therefore gaining importance, for example in buildings and green houses, for which novel organic PV materials are excellently suited. However, the performance of these materials critically depends on microstructure. Thus, slow and often destructive characterization methods are needed, severely retarding materials discovery towards a real breakthrough. To accelerate materials discovery, one would need to take the right decisions based on a faster assessment of microstructure. In the engineering world, digital twins are used for exactly that purpose, namely supporting real-time decisions even if information is scarce and indirect.

FAU Solar is teaming up with factory automation and artificial intelligence to learn how the concept of a Digital Twin could accelerate materials discovery. As a result, we propose a layout of a Digital Twin for PV materials, which has been recently published in “Joule”. The idea is to turn the famous “curse of dimensionality” from a problem into a feature: it is known that one can predict performance from microstructure but one can’t predict microstructure from performance, because many different microstructures would produce exactly the same performance. The point is however: if they do, then why distinguish them? All we need to know is the set of features that characterizes all these microstructures. Knowing the right features is the key to acceleration: on one hand, these features can be found by much simpler experiments, such as absorption spectroscopy. On the other hand, knowing the right features can also speed up physics models tremendously, which is why experts in solid state calculations and advanced mathematics are part of the consortium. In feature space, fast surrogate functions can be found which can be used to predict performance from structure, but most importantly, they can be used in the opposite direction, discovering new molecules with desired properties. Many of the enabling technologies still must be further developed to bring the digital twin to full performance, but even before these technologies are available, the digital twin can accelerate material science.