Basu, R., Siah, K. S., Distler, A., Häußler, F., Franke, J., Brabec, C. J., Egelhaaf, H. J.

Advanced Engineering Materials, 25(17), 2300322, 2023

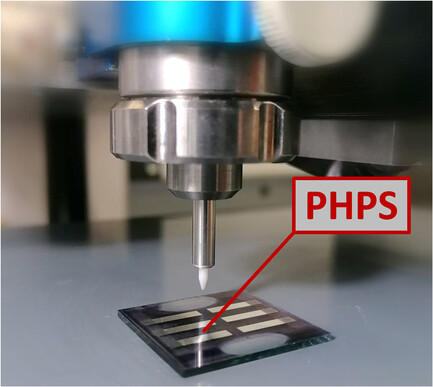

Organic electronic devices (OEDs) are prone to oxygen- and water-induced degradation and therefore need to be encapsulated with barrier materials. In this work, an aerosol jet (AJ)-printing process is developed to coat perhydropolysilazane (PHPS) directly onto OEDs by adapting the print setup and systematically optimizing the process parameters. Furthermore, a novel curing process that converts PHPS to silica barrier layers is developed by combining damp heat (DH) exposure with subsequent vacuum–UV irradiation. This two-step treatment is shown to be considerably faster and gentler than the state-of-the-art curing processes and also yields a quantitatively higher conversion. Both the printing and the conversion process are fully compatible with OED devices, which is demonstrated by a damage-free direct encapsulation of organic solar cells. The encapsulated cells show a significant reduction of degradation in DH conditions (65 °C/85% r.h.), maintaining >95% of their initial performance for >100 h. Complementary electroluminescence measurements reveal that the AJ-printed barrier layers effectively prevent lateral water ingress into the devices. Herein, the proof of principle is provided that AJ printing can be used to print barrier layers directly onto OEDs and is thus an industrially highly relevant technology to precisely encapsulate such devices even on 3D objects.

Basu, R., Siah, K. S., Distler, A., Häußler, F., Franke, J., Brabec, C. J., Egelhaaf, H. J.

Advanced Engineering Materials, 25(17), 2300322, 2023

Organic electronic devices (OEDs) are prone to oxygen- and water-induced degradation and therefore need to be encapsulated with barrier materials. In this work, an aerosol jet (AJ)-printing process is developed to coat perhydropolysilazane (PHPS) directly onto OEDs by adapting the print setup and systematically optimizing the process parameters. Furthermore, a novel curing process that converts PHPS to silica barrier layers is developed by combining damp heat (DH) exposure with subsequent vacuum–UV irradiation. This two-step treatment is shown to be considerably faster and gentler than the state-of-the-art curing processes and also yields a quantitatively higher conversion. Both the printing and the conversion process are fully compatible with OED devices, which is demonstrated by a damage-free direct encapsulation of organic solar cells. The encapsulated cells show a significant reduction of degradation in DH conditions (65 °C/85% r.h.), maintaining >95% of their initial performance for >100 h. Complementary electroluminescence measurements reveal that the AJ-printed barrier layers effectively prevent lateral water ingress into the devices. Herein, the proof of principle is provided that AJ printing can be used to print barrier layers directly onto OEDs and is thus an industrially highly relevant technology to precisely encapsulate such devices even on 3D objects.