Reitelshöfer, S., Martin, S., Nendel, F., Schäfer, T., Pham, D., Franke, J.

Electroactive Polymer Actuators and Devices (EAPAD) XXII (Vol. 11375, pp. 173-184). SPIE

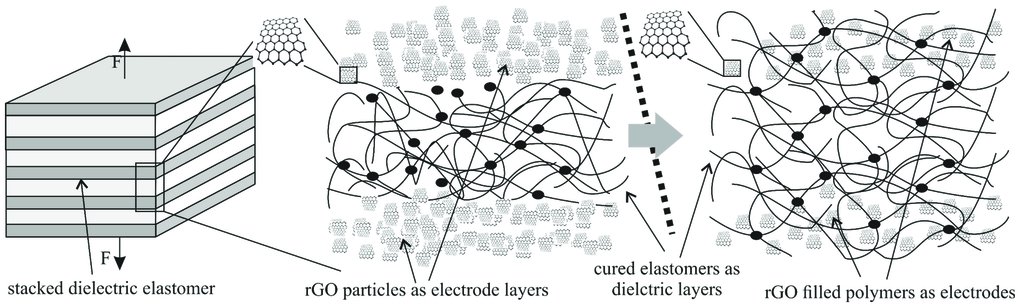

The efficient manufacturing of dielectric layers and electrodes for dielectric elastomers is challenging especially for stacked configurations. In an earlier publication we describe a contactless programmable manufacturing approach for aerosol-jet-printing stacked silicone and reduced graphene oxide (rGO)-layers in one process device. One limitation of the setup presented there is the long production time of e.g. 45 minutes for a 1 cm2 electrode with a sheet resistance of 1 MΩ. This contradicts the goal of printing numerous layers for stacked systems and is related to the usage of an ultrasonic atomizer. Therefore we present a new hybrid atomizer, which significantly lowers the printing times of rGO-electrodes. This hybrid atomizer again uses an ultrasonic aerosol generation system. Hence, particle-inks without chemical stabilizers that would affect the curing process of printed adjacent silicone structures, can still be used in the system over hours without agglomeration. In addition, a pneumatic aerosol generation is integrated with the new hybrid atomizer. The combined material output of the pneumatic and the ultrasonic approach allows for the printing of rGO-electrodes in two minutes or less with characteristics comparable to those described above. Furthermore, a light-heating-system is integrated into the printing system which enables the fast evaporation of the solvents independently of the height of the previously stacked layers. For this new system, several printing strategies are evaluated by comparing different programmed trajectories of the print head. Printed rGO-electrodes with thicknesses from 3-20 μm and values for the sheet resistance from 1 MOhm to 200 kOhm are characterized regarding their ability to bear a maximal deformation up to 100 % and repeated cyclic stretching up to 25 %

Reitelshöfer, S., Martin, S., Nendel, F., Schäfer, T., Pham, D., Franke, J.

Electroactive Polymer Actuators and Devices (EAPAD) XXII (Vol. 11375, pp. 173-184). SPIE

The efficient manufacturing of dielectric layers and electrodes for dielectric elastomers is challenging especially for stacked configurations. In an earlier publication we describe a contactless programmable manufacturing approach for aerosol-jet-printing stacked silicone and reduced graphene oxide (rGO)-layers in one process device. One limitation of the setup presented there is the long production time of e.g. 45 minutes for a 1 cm2 electrode with a sheet resistance of 1 MΩ. This contradicts the goal of printing numerous layers for stacked systems and is related to the usage of an ultrasonic atomizer. Therefore we present a new hybrid atomizer, which significantly lowers the printing times of rGO-electrodes. This hybrid atomizer again uses an ultrasonic aerosol generation system. Hence, particle-inks without chemical stabilizers that would affect the curing process of printed adjacent silicone structures, can still be used in the system over hours without agglomeration. In addition, a pneumatic aerosol generation is integrated with the new hybrid atomizer. The combined material output of the pneumatic and the ultrasonic approach allows for the printing of rGO-electrodes in two minutes or less with characteristics comparable to those described above. Furthermore, a light-heating-system is integrated into the printing system which enables the fast evaporation of the solvents independently of the height of the previously stacked layers. For this new system, several printing strategies are evaluated by comparing different programmed trajectories of the print head. Printed rGO-electrodes with thicknesses from 3-20 μm and values for the sheet resistance from 1 MOhm to 200 kOhm are characterized regarding their ability to bear a maximal deformation up to 100 % and repeated cyclic stretching up to 25 %